Our Shop

Contact us for all your questions and opinions, or you can solve your problems in a shorter time with our contact offices.

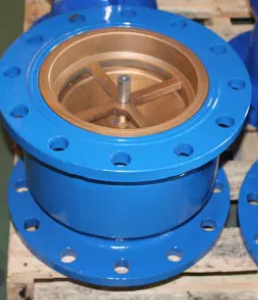

Check Valve

Valves only is the greatest Check Valve Manufacturers in USA. A check valve, also called a non-return valve, is a device that allows fluid liquid or gas to flow in one direction only. They play an important role in a wide range of industrial operations, preventing backflow and maintaining proper operation. They are highly corrosive resistance used in a wide range of industrial operations.

These valves consist of a disc or ball or diaphragm, when fluid flow its pressure moves the ball or disc which moves the component from the seat and makes a passage path for the fluids to flow and when there is a reverse flow occurs the pressure moves the component toward the seat which blocks. These valves are simple in design and have fewer moving parts which work on the basics of flow direction, protecting equipment damage which is caused by the reverse flow.

It works on a relatively simple principle. It works based on the fluid’s differential pressure. When the pressure on the upstream side (inlet) increases that on the downstream (outlet), the valve opens and flow begins. If the flow reverses, the pressure on the downstream side rises, the valve closes and prevents the fluid from flowing in the opposite direction. When the forward pressure drops, check valves typically return to their closed position using a spring mechanism or gravity.

Check valve types:

●Swing check valve

●Ball check valve

●Lift check valve

●Dual plate check valve

●Silent check valve

●Non slam swing check valve

●Tilting disc check valve

●Pressure seal check valve

●Foot Check valve

●Piston check valve

Check Valve Manufacturers in USA are an essential part in many fluid systems, provide reliable and effective solutions for preventing backflow and help in maintaining pressure, and protecting equipment. Their Simple design, low maintenance make them widely used in different industrial, commercial, and residential applications.

Description:

Body Material- Cast Iron and Cast Steel (LF2, A216, WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F91), DUPLEX AND Super duplex STEEL [ F51, F53,F55 ] Forged Steel A105, A105N, F11, F22, F304, F316, F91] , Alloy20 , Hastelloy ALBR.

Size- ½” – 80”

Class-150 – 2500; PN10 – PN-450

Ends- Threaded, socket weld, butt weld, flanged, lug, wafer.

Showing all 7 results