Our Shop

Contact us for all your questions and opinions, or you can solve your problems in a shorter time with our contact offices.

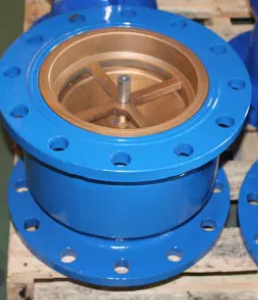

CHECK VALVE

Valves Only is a trusted Check Valve Manufacturers in USA, providing high-quality check valves designed to prevent backflow and ensure smooth fluid flow. As one of the top names in the industry, we offer durable and effective solutions. Our check valves, which prevent reverse streams, increase the reliability of the system by allowing fluid to flow in one direction.

Key Parts of a Check Valve:

1)Valve Body: The main structure that houses internal components.

2)Disc or Ball: Moves freely to allow or block fluid flow.

3)Seat: Ensures a tight seal to prevent leakage.

4)Spring (in some designs): Helps the valve close quickly to stop backflow.

5)Hinge or Swing Arm (for swing check valves): Controls the disc movement based on flow direction.

Working Mechanism:

It works automatically and require no external control. When the liquid flows in the desired direction, the pressure ball or disc away from the seat to allow passage. If the flow is reversed, the gravity or a spring mechanism moves the disc back to the seat, seals the valve and prevents backflow. It examines the valves required to maintain the efficiency of the self -regulation function system.

Advantages of Using Check Valve:

1)Prevents Backflow

2)Low Maintenance

3)Automatic Operation

4)Versatile Applications

Types:

1)Swing Check Valve

2)Ball Check Valve

3)Lift Check Valve

4)Dual Plate Check Valve

5)Silent Check Valve

6)Non-Slam Swing Check Valve

7)Tilting Disc Check Valve

8)Pressure Seal Check Valve

9)Foot Check Valve

10)Piston Check Valve

Industries:

1)Oil & Gas

2)Chemical Processing

3)Water & Wastewater Treatment

4)Power Generation

5)Hydraulic Systems

6)Automotive

Description:

Body Material- Cast Iron and Cast Steel (LF2, A216, WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F91), DUPLEX AND Super duplex STEEL [ F51, F53,F55 ] Forged Steel A105, A105N, F11, F22, F304, F316, F91] , Alloy20 , Hastelloy ALBR.

Size- ½” – 80”

Class-150 – 2500; PN10 – PN-450

Ends- Threaded, socket weld, butt weld, flanged, lug, wafer.

Conclusion:

Check Valves are important to ensure unidirectional fluid flow and prevent system errors. Valves Only, a reliable Check Valve Manufacturers in USA- provides high quality check valves that fit industrial needs. Contact us today for the best backflow prevention solutions!

Showing all 9 results