Our Shop

Contact us for all your questions and opinions, or you can solve your problems in a shorter time with our contact offices.

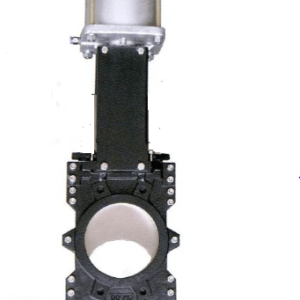

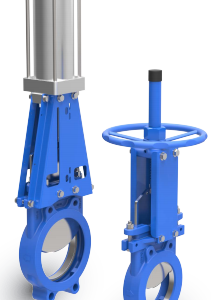

Knife Gate Valve

Valvesonly is the prominent Knife gate valve manufacturers in USA. It is a type of gate valve made to handle slurry, abrasive materials, and viscous fluids is the knife gate valve. It is extensively used in a variety of industries, including chemical processing, pulp and paper, mining, and wastewater treatment.

Working:

It works by raising a flat, sharply edged gate out of the fluid’s path. When the valve is opened, the fluid is able to pass through the entire bore of the valve because the gate is drawn up into the valve body. The gate stops the flow when it is closed by being pushed down to cut through the liquid and seal against the seat. The name “knife gate valve” comes from this cutting action, which also makes it especially useful for managing materials that could clog or harm other valve types.

Function:

Controlling or isolating the fluid flow within a system is the main purpose of a knife gate valve. For on/off and isolation applications, it works exceptionally well. Knife gate valves guarantee a tight seal, preventing leaks and preserving the integrity of the piping system because of their cutting ability through fibrous and thick materials.

Features:

Sharp Knife-Edge Gate: This gate’s sharp edge provide a clean and dependable shut-off by cutting through thick, solid media.

Robust Construction: it is made to withstand severe conditions and are usually composed of cast iron, stainless steel, or other resilient materials.

Full Bore Design: The valve uses less energy and produces less pressure drop when it is fully open, allowing minimal flow resistance.

Knife gate valve manufacturers in USA are critical in systems dealing with challenging fluids and materials, offering reliability, efficiency, and durability.

Industries which use them:

•Mining Industry

•Pulp and paper Industry

•WasteWater Treatment Plant

•Chemical Industry

•Power Generation Plant

Description:

Available materials: WCB, WC6, WCC, LCB, LCC, Cast iron, Ductile Iron, SS316, SS304

Size: 2″ to 80″

Class: 150 to 300

Nominal Pressure: PN6 to PN40

Operation: Handwheel, Electric and Pneumatic Actuated, Gear operated

Ends: Wafer, Lug, Flanged

Showing all 5 results