Our Shop

Contact us for all your questions and opinions, or you can solve your problems in a shorter time with our contact offices.

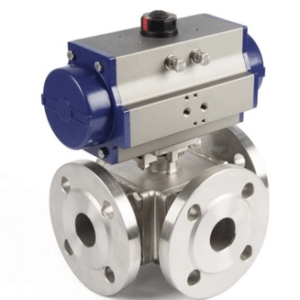

Pneumatic Actuated Ball Valve

ValvesOnly is a reputable Pneumatic Ball Valve Manufacturers in USA. A ball inside the valve body opens and closes automatically with the use of compressed air or other gasses in a pneumatically operated ball valve. This technology finds extensive application in industrial settings where accurate fluid flow control is crucial. A spherical ball with a through hole that is housed inside the valve body is the essential part of this valve. Depending on the intended operation, the pneumatic actuator either rotates the ball to permit fluid flow or positions it to restrict the flow when it is engaged.

Functions:

Valvesonly being top Pneumatic Ball Valve Manufacturers in USA provides valves with these functions:

1)Flow Regulation: These valves enable for accurate flow control by adjusting the fluid flow through rotation of the V-shaped ball. This is helpful in industrial processes where it’s important to maintain precise flow rates.

2)Rapid Shut-Off: These valves provide the ability to quick fluid flow, which makes them widely used in emergency situations where quick stop of fluid flow is needed, like emergency shut-off or leak control.

3)Pneumatic V-ball valves provide excellent flow control precision due to their V-shaped ball design, which makes them appropriate for applications needing precise flow parameters.

Working:

The Pneumatic Ball Valve Manufacturer in USA has the valve which merely needs pressurized air to enter the pneumatic actuator; the air source rotates the ball core in a range of 0 to 90 degrees, and the ball valve’s switch is controlled by a tiny turning torque. To regulate the ball valve, the valve positioner can be assembled based on the operating conditions. The medium flow can be altered by adjusting the core’s opening. To achieve opening, the sphere revolves around the valve body’s midline, with a circular channel or through-hole running through its axis. The valve is tightly closed when the ball’s center rotates to a 90° angle.

Parts:

●Valve Body

●Ball

●Seats

●Stem

●Pneumatic Actuator

●Positioners and Sensors

●End Connections

Industries:

●Oil and Gas

●Chemical Processing

●Water Treatment

●Petrochemical

●Power Generation

●Pulp and Paper

●Mining

●Automotive

●Aerospace

●Marine

●Textiles

●Renewable Energy (e.g., Wind and Solar)

●General Manufacturing

●Wastewater Treatment

Advantages:

●Fast response time

●Precise control

●Automation

●Versatility

●Durability

●Reliability

●Bi-directional control

●Compact design

●Cost-effective

●Suitable for harsh environments

Temperature:

●Standard -4°F to 200°F (-20°C to 93°C)

●Low -40°F to 176°F (-40°C to 80°C)

●High 0°F to 300°F (-18°C to 149°C)

Configuration of a Pneumatic Actuator:

●4-20 Mamp

●Pneumatic single acting actuators

●Pneumatic double acting actuators

●Pneumatic rotary actuators

●Pneumatic Scotch and Yoke actuators

●Pressure: 228 bar

Description:

●Pneumatic Ball Valve Manufacturer in USA has the valve with this specifications

●Available materials: WCB, WC6, WCC, LCB, LCC, Cast iron, Ductile Iron, SS316, SS304

●Size: 2″ to 80″

●Class: 150 to 300

●Nominal Pressure: PN6 to PN40

●Operation: Pneumatic Actuated

●Ends: Flanged, Threaded, Socket and Butt Weld

Showing all 6 results