UNDERSTANDING THE DIFFERENT TYPES OF AIR VALVES: SINGLE VS. DOUBLE ORIFICE

Valves Only is a world-renowned industrial valve solution manufacturer and supplier of dependable and efficient pipeline system components. The most crucial type of valve we supply is the air valve, which is designed to maintain pipeline efficiency and protection. In this article, we will be Understanding the Different Types of Air Valves: Single vs. Double Orifice, providing you with the clarity of how they work, where they are applied, and why selecting the right one is important for your operations.

Definition: What Are Air Valve?

Air valves are automatic devices fitted within pipeline systems to discharge or accept air when the system operates. They are meant to remove entrapped air pockets, avoid vacuum conditions, and improve hydraulic pipeline performance.

Two primary air valves exist:

- Single Orifice Air Valve – Alternatively referred to as an air release valve, it mainly releases tiny air bubbles during system functioning.

- Double Orifice Air Valve – Also referred to as an air & vacuum valve or a combination air valve, it functions for both air release and vacuum break, accepting big volumes of air during filling and draining procedures and releasing built-up air.

Being aware of the differences among them guarantees maximized performance and system life.

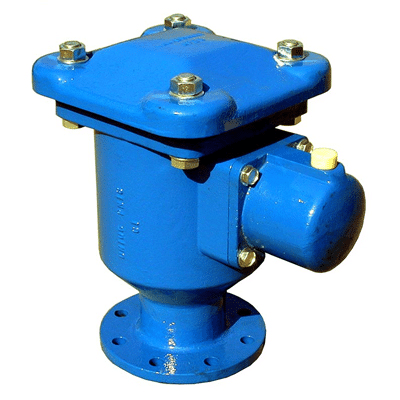

Key Components of Single and Double Orifice Air Valve

Although their structures differ slightly, both single and double orifice air valves have essential parts that enable them to work effectively under pressure and changing flow conditions.

Essential Parts Include:

- Valve Body – Usually constructed using ductile iron, cast iron, or stainless steel to resist pressure and corrosion.

- Float Mechanism – Moves up and down depending on air or fluid availability, facilitating valve opening or closing.

- Orifice (Single or Dual) – Small holes for air to enter or exit. The number of orifices determines the type of valve.

- Seal/Gasket – Provides a watertight seal to avoid leakage of water.

- Cover/Bolted Cap – Shields inner parts and provides easy access for servicing.

- Lever Assembly (in certain designs) – Manually assists in opening/closing as per float movement.

Working Mechanism of Single vs. Double Orifice Air Valve

Single Orifice Air Valve:

This valve regularly vents small amounts of air that build up at top points in a pipe. When the system is operating, air bubbles float to the surface of the valve. The float within descends as air comes in, opening the orifice and venting air. When water hits the valve, the float ascends, closing the orifice to keep fluid from leaving.

Double Orifice Air Valve:

This is a combination of air release and air/vacuum in one body. It has a large orifice for venting or admitting large amounts of air (in pipeline filling or emptying), and a small orifice for steady air release during regular operation. The large orifice will open when there is vacuum creation (e.g., in case of sudden drainage or pipe burst), to avert possible pipe collapse.

This two-way action renders the double orifice valve extremely versatile and crucial in dynamic systems.

Advantages of Single and Double Orifice Air Valve

Every air valve type has its own advantages, based on use.

Advantages of Single Orifice Air Valve:

- Uninterrupted air release throughout system operation.

- Eliminates air pockets, enhancing flow efficiency

- Space-saving and easy to install.

- Decreases pipeline damage risk from air accumulation.

Advantages of Double Orifice Air Valve:

- Accommodates big air discharges in pipe filling.

- Permits air in vacuum situations (pipe draining or abrupt shutdown).

- Avoids pipe collapse through pressure equalization.

- Provides constant small air release in normal operation.

- Flexible for application in pressurized or non-pressurized systems.

Industries Utilizing Air Valve

Air valves are a must in any fluid transport system in which pressure regulation and air removal are vital. Some of the principal industries are:

- Water Supply and Distribution – Prevents air blockages, providing continuous flow.

- Wastewater Treatment Plants – Removes air during sludge or effluent movement.

- Irrigation Systems – Provides constant flow through long-distance pipelines.

- Mining – Manages slurry lines and pipeline integrity.

- Oil & Gas – Applied in refined product pipelines and offshore operations.

- Chemical and Process Industries – Where air management is critical for system safety and efficiency.

- Power Plants – In cooling water circuits and condensate return lines.

Why Are Air Valves Necessary?

Air in a piping system is more than just an annoyance—it’s a significant hazard. Absent proper air valve installation:

- Air pockets can constrict flow, causing energy loss and inefficient pumping.

- Negative pressure (vacuum) can lead to pipe collapse or pipe deformation.

- Water hammer impacts from violent release of air can damage equipment.

- Trapped air can cause inaccurate flow measurements.

- In sewer lines, air accumulation can restrict flow or lead to surging.

- Single and double orifice air valves automatically control air in the system, safeguard equipment, improve efficiency, and maintain operational safety.

Why Purchase Air Valves from Valves Only?

Valves Only is dedicated to delivering premium-quality, trustworthy air valves meeting international standards and outperforming expectations. Here’s why clients worldwide trust us:

- Certified Quality – Our valves are tested to international standards.

- Durable Material Selection – Ductile iron, carbon steel, and stainless steel for long-lasting performance in any setting.

- Customized Solutions – From small municipal lines to industrial systems, we provide air valves suitable for your particular requirements.

- Competitive Pricing – High-quality without the high price.

- Fast Delivery – Strategically placed stock points assure prompt order shipping.

- Technical Capability – Our in-house engineering team offers full service support for sizing, selection, and installation.

Whether you’re dealing with a municipal water system or a sophisticated industrial pipeline, the selection of an air valve can make or break system performance and protection. This guide has offered a complete look at Understanding the Different Types of Air Valves: Single vs. Double Orifice, so that you can best determine the optimal solution for your operational requirements.

At Valves Only, we provide high-performance air valves to ensure your pipelines are efficient, safe, and reliable. Contact us today to talk about your project needs, and we’ll assist you in finding the perfect valve for your system.