BI-DIRECTIONAL VS. UNI-DIRECTIONAL KNIFE GATE VALVES: WHICH ONE DO YOU NEED?

Valves Only is a high-performance industrial valve company and distributor that serves the diversified needs of various industries like wastewater treatment, mining, pulp and paper, and chemical processing. One of our most popular product offerings is the knife gate valve because it can cut through heavy, sticky media with minimal resistance. One of the most common questions our clients ask us is: Bi-Directional vs. Uni-Directional Knife Gate Valves: Which One Do You Need? In this article, we analyze the key differences between these two valves, their uses and how to choose the right one for your system.

Definition

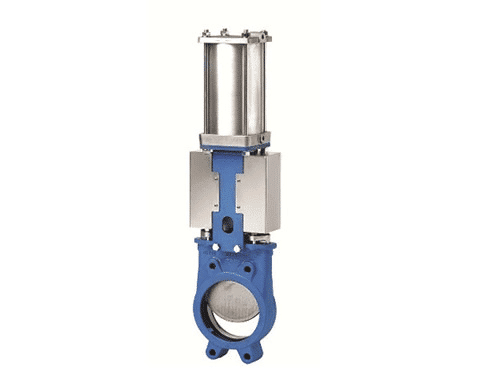

A knife gate valve is a type of shut-off valve that is specially designed to handle slurry, viscous and abrasive media. It has a sharp edged gate cutting through heavy flow which make it an ideal option for on off and isolation services in harsh condition. There are two significant variants of such valve:

Uni-Directional Knife Gate Valve: Specially designed to shut off against flow from one direction. It is most suitable for systems where the flow is predictable and constant in one direction.

Bi-Directional Knife Gate Valve: Specially designed to offer tight shut-off in both directions. It can accommodate reverse flows or systems with changing pressure and flow directions.

Knowing which one is right for your application is essential to provide operational dependability and avoid leakage or valve failure.

Essential Components

- Valve Body: Generally constructed from cast iron, stainless steel, or carbon steel. The body design in bi-directional valves is symmetrical to provide pressure handling from both sides.

- Gate: A sharpened, flat blade that travels up and down to open or shut the valve. Used to cut through the media.

- Seat: Uni-directional valves contain seats on the downstream side alone, whereas bi-directional valves possess seats on both sides.

- Packing/Gland Area: Closes the stem and avoids leakage from the outside.

- Actuator: Manually operated (handwheel), pneumatically, electrically, or hydraulically.

Working Mechanism

The fundamental principle of operation remains the same for both: the gate goes down to shut flow and up to open flow. The distinction becomes apparent in how the valve controls pressure and seals against it, though.

Uni-Directional Valve:

- Valve seat is on the downstream side.

- Constructed to withstand flow pressure from a single direction.

- When flow reverses, the gate can fail to seat, causing leakage.

Bi-Directional Valve

- Has seating arrangements on upstream and downstream sides.

- Delivers a close shut-off independent of the flow direction.

- Fitted with wedge or elastomer seats that close on both sides when the gate is shut.

This makes bi-directional valves more versatile but slightly more costly because of their improved construction and sealing mechanisms.

Advantages

Uni-Directional Knife Gate Valve:

- Low Cost: Simpler design translates to lower production and maintenance costs.

- Ideal For Unpredictable Flow: Excels where flow is ever-changing from a single direction.

- Lightweight: Reduced amount of material used, making it simpler to install and move around.

Bi-Directional Knife Gate Valve:

- Flexible Flow Control: Functions well in systems where the direction of flow can shift.

- Improved Safety: Blocks backflow and leakage even when reversed under pressure.

- Increased Lifespan: Designed for longevity in fluctuating or unpredictable situations.

Industries That Utilize Knife Gate Valve

- Wastewater Treatment: For minimum clogging of sludge and slurry.

- Mining: Utilized in thick slurry pipelines transporting ores and abrasive particles.

- Pulp & Paper: Suitable for pulp stock, paper slurries, and recycled products.

- Power Plants: In ash handling and cooling water systems.

- Chemical Processing: Treats corrosive and abrasive fluids under fluctuating pressures.

Why Are They Necessary?

Knife gate valves are vital in service where regular valves would experience clogging or wear. Capable of cutting abrasive or thick media and holding a tight seal under severe conditions, they are particularly well-suited for:

- Slurry and Viscous Media: Where globe or butterfly valves would be unsuccessful.

- Abrasive Environments: Like mining, where valve life is paramount.

- Isolation Applications: Where zero leakage during maintenance is critical.

The option between bi-directional and uni-directional types also enables users to customize the valve choice to their individual flow needs. The wrong type can result in system inefficiencies, constant maintenance, or even dangerous leaks.

Why Purchase from Valves Only?

Valves Only is dedicated to providing quality, reliability, and performance. Here’s why we are the go-to supplier for knife gate valves worldwide:

- Precision Engineering: Our valves are engineered with the latest tools and produced using high-quality raw materials.

- Complete Range: We have both bi-directional and uni-directional knife gate valves available in multiple sizes, materials, and actuation.

- Corrosion-Resistant Materials: Stainless steel, duplex, and other alloys available for extreme chemical and corrosive conditions.

- Global Reach: Through effective supply chains and distribution networks, we provide services to clients in many countries.

- Technical Support: From procurement to installation, our engineers are fully committed to help you with the correct valve for your requirement.

- Competitive Pricing: Despite top-notch quality, we offer extremely competitive pricing without compromising performance.

Whether you are rebuilding a wastewater treatment plant or placing a new slurry line within a mine, Valves Only makes sure you receive the top valve for your process with the performance and longevity your system requires.

Bi-Directional vs. Uni-Directional Knife Gate Valves: Which One Do You Need is a matter of knowing your system’s direction of flow and pressure situation. If your process is all about steady, single-direction flow under stable pressure conditions, then a uni-directional valve will provide cost-efficient performance. But if your process is all about reversing flow directions or the occurrence of backpressure, then shelling out for a bi-directional valve is the wiser option for safety and reliability.

At Valves Only, we assist you in making this decision confidently so that you receive a valve that is not only functional but also optimal. From design to material selection and after-sales assistance, we are here with you throughout the journey. Choose right with Valves Only-the leaders in industrial flow control solutions.

Recent Posts

- What Is a Steam Trap and How Does It Work?

- What Is a Foot Valve and Why Is It Used in Pumping Systems?

- BI-DIRECTIONAL VS. UNI-DIRECTIONAL KNIFE GATE VALVES: WHICH ONE DO YOU NEED?

- WHAT IS A DOUBLE BLOCK AND BLEED BALL VALVE? A COMPLETE GUIDE

- UNDERSTANDING THE DIFFERENT TYPES OF AIR VALVES: SINGLE VS. DOUBLE ORIFICE