Our Shop

Contact us for all your questions and opinions, or you can solve your problems in a shorter time with our contact offices.

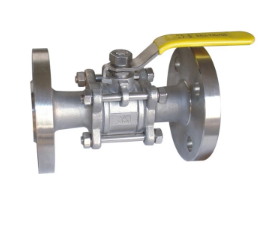

INCONEL VALVE

Valves Only is a prominent Inconel Valve Manufacturers in USA provides quality Inconel valves appropriate for reliability, efficiency, and durability. Due to its excellent corrosion resistance, oxidation, and thermal shock resistance, Inconel valves are appropriate for severe environments. These highly used valves in sectors such as power generation, chemical processing, and space travel are constructed from Inconel, a nickel-chromium alloy superalloy.

Key Parts of a Inconel Valve:

1)Valve Body: Constructed using Inconel for increased strength and resistance to corrosion.

2)Disc, Gate, or Ball: Controls flow of fluid according to valve type.

3)Stem: Connects closure mechanism to handwheel or actuator.

4)Seat rings: To prevent leakage, form a tight seal.

5)Bonnet: Gives protection and safety to internal components.

6)Handwheel/actuator: Facilitates automatic or manual operation of the valve.

Working Mechanism:

Inconel valves open, shut, or restrict partially the path to regulate gases, steam, or fluid flow. Based on the kind of valve, it can provide complete shut-off, provide precise throttling, or allow free flow. Where normal materials would be worn away by elevated temperatures and pressures, these valves are ideal.

Advantages of Using Inconel Valve:

1)High-Temperature Resistant: Inconel valves are able to perform efficiently in very hot temperatures.

2)Excellent Corrosion Resistance: Ideal for rough chemicals and marine environments.

3)Superior Mechanical Strength: Can resist heavy pressure.

4)Leak-Proof Design: Ensures efficient performance and safe closure.

5)Long Life Service: Reduces downtime and maintenance costs.

Types:

1)Inconel Gate Valve: Ideal for on/off service.

2)Inconel Globe Valve: Provides throttling capability.

3)Inconel Ball Valve: Offers quick shut-off and high flow.

4)Inconel Check Valve: Prevents backflow in pipelines.

Industries:

1)Aerospace & Defence

2)Chemical Processing

3)Oil & Gas

4)Power Generation

5)Marine & Offshore

Description:

Materials: Inconel 625 and Inconel 600

Class: PN10/ 16

Size: 1/2″-4″(DN15-DN100), (DN25-DN200)

Operation: Electric actuated, pneumatic actuated, Handwheel operated, gear operated, lever operated

Ends: Flanged, wafer, buttweld, socket weld, lug, threaded

Conclusion:

One of the leading Inconel Valve Manufacturers in USA, Valvesonly offers high-performance valves that meet stringent industry standards. In demanding industrial applications, our Inconel valves are engineered to be as long-lasting, efficient, and corrosion resistant as possible.

Showing all 11 results