Our Shop

Contact us for all your questions and opinions, or you can solve your problems in a shorter time with our contact offices.

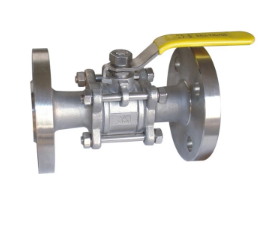

Inconel Valve

Valvesonly is said to have specialization Inconel Valve Manufacturer in USA and these are marketed both to the international clients as well as to the local clients.

About

A Valve manufacturer of Inconel is a company dealing specifically in valves that have been produced from Inconel which refers to a series of metallic alloy that has a high resistance to factors such as heat, corrosion and oxidation. These valves are significantly employed in aircraft industries, chemicals, oil & natural gasses industries and in marine sectors where operation conditions are high and hence the performance of the valves is highly required.

Working Mechanism:

Inconel valves work based on opening or closing the passage of fluids or gaseous substances through a particular system. They have been designed for high temperatures and pressures which are favorable where normal materials would not be appropriate. The working mechanism depends on strict accuracy of the components’ manufacturing and their subsequent assembly with minimal gaps to be able to work for many hours without failure. They can be manufactured in gate valves, globe valves, ball valves, or check valves which all have their particular purpose of controlling the flow direction, pressure or backflow. The two often possess a strong physical structure and they are able to endure severe chemical conditions or high temperatures.

Parts:

Inconel Valve Manufacturer deals with these parts to build valves.

●Body and Bonnet: The outer casework of the valve that encases the internals and forms the main body of the valve.

●Trim: Refers to the parts of the valve that are in contact with the fluid or gas to be regulated and these include the stem, disc and the seating.

●Actuator: Component through which the valve is operated, this can either be a hand wheel or lever, motor, compressed air, or hydraulic fluid operated.

●Seals and Gaskets: There should be a very close tolerance so that there is a good fit between the various components of the valve and the body, particularly to minimize or prevent leakage of fluids or gasses..

●Connections: Bosses or threads that enable the valve to be screwed onto pipes or any other part of the system in question.

Advantages:

●High Temperature Resistance

●Corrosion Resistance

●Strength and Durability

●Higher resistance to oxidation and corrosion

●Durability and dependability in unfavorable conditions

●Versatility in Types

●Economical in the long run

●It guarantees the safe and effective functioning of the business.

●Wide Application Range

●Minimal Maintenance

●Safe Operation

●Very good mechanical characteristics at high temperatures

●Ideal for use in various industries

●Lower possibility of mechanical failure

We are Inconel Valve Manufacturer, serving industries like:

●Petrochemical Industry

●Power generation Industry

●Oil and gas Industry

●Chemical Processing Industry

●Marine Industry

●Automotive Industry

●Mining Industry

●Water Treatment Industry

●Semiconductor Manufacturing

●Pulp and Paper Industry

●Nuclear Industry

Description:

●Materials: Inconel 625 and Inconel 600

●Class: PN10/ 16

●Size: 1/2″-4″(DN15-DN100), (DN25-DN200)

●Operation: Electric actuated, pneumatic actuated, Handwheel operated, gear operated, lever operated

●Ends: Flanged, wafer, buttweld, socket weld, lug, threaded

Showing all 5 results