Our Shop

Contact us for all your questions and opinions, or you can solve your problems in a shorter time with our contact offices.

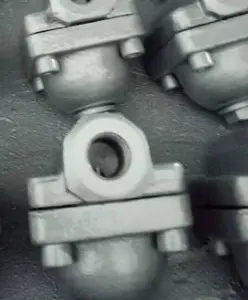

Pressure Seal Globe Valve

ValvesOnly is the foremost pressure seal globe valve manufacturers in USA , is specifically designed for industrial applications as anti-high pressure and temperature.

Working

the flow of fluid through a movable disc-also known as a plug, moving up and down against a seat. In this type, when the disc is raised, the flow is allowed to pass through the valve; the flow is blocked whenever it is lowered. Fluid enters the valve body, proceeds past the area of the seat, and exits through the outlet. In most cases, the disc or plug is operated by a stem attached to an actuator or handwheel.

Below are the advantages of pressure seal globe valve manufacturers

Improved Leak Prevention

Enhanced Safety

Durability and Longevity

Reduced Maintenance

Industries using

Oil and gas

Power generation

Petrochemicals

Defense and aerospace

Water and wastewater

Components

Body: This is the main structure with pressure in the valve. The body is usually cast iron, carbon steel, stainless steel, or alloy material.

Bonnet: It is the top most part of the valve which covers the stem and packing.

Stem: This is a threaded rod that joins the valve disc with the actuator or handwheel. The stem provides mechanical strength to deliver torque.

Disc: Pressure retaining member which controls the passage of media.

Seats: Pressure retaining member.

Bolts: Provides mechanical strength.

Handwheel: Provides mechanical strength to transmit torque.

Packing: A sealing arrangement that prevents leakage.

Bellows seal: A seal which prevents leakage

Segmental thrust ring: Absorbs the thrust applied by internal pressure.

Seal ring: It prevents deformation of the top valve surface .

Gasket: it is made of high density graphite, removable without damaging the sealing surface.

Description:

1. Body Material: Cast Iron, Cast steel [A216 WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91]

2. Class: 150 – 2500; PN10 – PN 450

3. Size: DN 10 – DN 1200

4. Ends: Butt Weld, Flanged, Threaded, Socket Weld

5. Operations: Hand-wheel Operated, Pneumatic Actuated, Electric Actuated, Gear Operated

Showing the single result