Our Shop

Contact us for all your questions and opinions, or you can solve your problems in a shorter time with our contact offices.

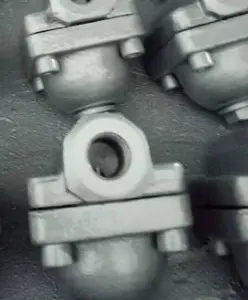

Strainer

Valvesonly is said to be the premier Strainer Manufacturers in USA.

About

Strainer Manufacturer are involved in the production of crucial tools utilized in filtering equipment in numerous industries. Filters are used in fluid management systems to prevent clogging of equipment and control of damaging particles and foreign bodies from liquids and gases. These are manufacturers who are special in engineering strong strainer solutions that meet the desired quality standards and the need of operation in the various industries including oil and gas industries, chemical industries, water industries, food and beverage industries and the pharmaceutical industries. They focus on inventiveness, dependability, and versatility to provide products that address customer’s needs of controlling and safeguarding the downstream equipment.

Working Mechanism:

Strainer manufacturers in USA works as to prevent and arrest particulates that can cause harm or hinderance to the fluid flow within a certain system. When the fluid is passing through the strainer body particularly that has a perforated or mesh filtering element then the particles greater than the size of the mesh openings are captured while the clean fluid goes forward. The captured contaminants are periodically removed through cleaning or replacement of the straining element in order to keep the operation continuous and the efficiency of the system intact. The basic mechanism of strainers is filtering where screen size and configuration is used in defining the effectiveness and trapping capability of the strainer.

Parts :

1. Body: The main housing of the strainer is built from Stainless steel, Carbon steel or exotic alloys to accommodate the pressure and corrosive atmosphere.

2. Screen or Element: The filtering component located in the strainer body and most often made of perforated metal, wire mesh or synthetic materials.

3. Basket or Housing: The element that is to be positioned within the strainer body that holds it securely in position to allow easy installation and removal as well as cleaning.

4. Cover or Lid: Holds the straining element and gives a channel for easy repair and cleaning without affecting the pipeline.

5. Connections (Inlet/Outlet): Valves for open and shut on/off access to pipelines, that are custom-built to fit into pipelines so as to allow the flow of the fluids.

6. Drain Valve (Optional): We as a strainer manufacturers in USA makes valves used to remove the debris collected in the strainer body and this operation can be done without removing the strainer body from the unit hence reducing on time taken for maintenance.

Advantages

1.Protection of Equipment: They provide protection against erosion and abrasion by debris and solid particles on the equipment such as pumps, valves.

2.Enhance System Efficiency: They ensure that the fluid move in a smooth and undisturbed manner through the system by eliminating the impurities from them which increase the efficiency of the system.

3.Cost savings: restricting blockage and restricting harm to the equipment reduces the costs of maintenance and time off.

4.Versatility: Strainers are useful in various applications and industries such as water treatment, oil and gas, chemical processing and others and it come in various types and sizes.

5.Simple Maintenance: Many of them have characteristics that allow easy cleaning and easiness in accessing the inside of the containers..

6.Customizability: The screens or meshes of the strainers can be of any type depending on the specific filtration requirement that needs to be met.

7.Reliability: In general, strainer are reliable and durable, designed for pressure and temperature service.

8.Environmental Protection: Our valves at strainer manufacturers in USA is useful in avoiding pollution and protection of the environment as it holds the dirt and other unwanted materials.

We are Strainer Manufacturers in USA, serving industries like:

●Water Treatment Plants

●Oil and Gas Industry

●Chemical Processing

●HVAC Systems

●Power Generation

●Pulp and Paper Industry

●Marine Applications

●Automotive Industry

Description:-

1.Available materials: WCB, WC6, WCC, LCB, LCC, CF8, CF8M, cast iron, SS304, SS316, ductile iron, Carbon steel( ASTM A105, ASTM A516), Stainless Steel( ASTM A182 F304, ASTM A182 F316), Brass( ASTM B16, ASTM B124)

2.Class: 125 to 300

3.Nominal Pressure: PN6 to PN25

4.Size: ½” to 32”

5.Ends- Flanged, threaded, Buttweld, socket weld

Showing all 2 results