Our Shop

Contact us for all your questions and opinions, or you can solve your problems in a shorter time with our contact offices.

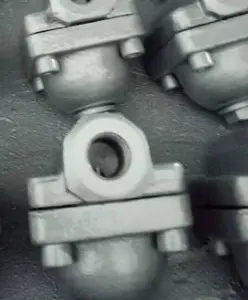

Triple Duty Valve

ValvesOnly is a topmost Triple Duty Valve Manufacturer in USA. Triple duty valves combine a shut-off valve, check valve, and balancing/throttling valve—three distinct valve types generally found on the discharge side of a hydronic pump system—into one. By far the biggest benefit of the triple duty valve is its ability to save space in packed mechanical rooms by combining these valves.

Additionally, there are frequently significant cost advantages when utilizing a multi-purpose triple duty valve. You simply have to pay for one valve as opposed to three separate ones. This results in significantly shorter installation times, which lowers expenses even further. Triple duty valves are a very cost-effective option.

Working:

Turn Off the System

Both disc- and ball-style triple duty valves offer positive shut-off, which enables the pump to be isolated from the rest of the system. If your triple duty valve features a ball, it rotates to open or close. The ball is hidden and has a hole in the middle. Similar to this, a triple duty valve disc will rotate and move in a “cam” motion toward the seat, increasing seating pressure. It is therefore possible to achieve tight flow shut-off even while utilizing metal disks and seats.

Prevention of Backflow

By limiting the fluid’s flow in one direction, the check valve part of a triple duty valve stops backflow and gravity circulation in pumping systems, protecting the pump and reducing unintentional heat transfer through the system. Furthermore, a non-slam check valve that allows for silent operation is a feature seen on a lot of triple duty valves.

Maintenance of Flow Rate

Within a triple duty valve, the balancing or throttling valve function regulates the system flow rate to maximize operating efficiency and provide exact flow within a maximum control range. To reset the valve in the proper position after shut-off, the majority of triple duty valves feature a memory stop and pre-set balance.

Parts:

•Body

•Disc

•Seat

•Stem

•Bonnet

•Handle or Actuator

•Spring (for check function)

•Gaskets

•Packing

•Flow Measurement Ports

•Balancing Mechanism

Industries:

•Water treatment

•Plumbing

•Municipal water supply

•Industrial manufacturing

•Chemical processing

•Oil and gas

•Power generation

•Mining

•Pulp and paper

•Marine and shipbuilding

•Wastewater treatment

•Textile manufacturing

•Automotive manufacturing

Advantages:

The topmost Triple Duty Valve Manufacturer has the valve with these advantages

1.Multifunctionality: Provides shut-off, balancing, and check operations all in one valve.

2.Space-saving: By reducing the number of valves and fittings required, pipe systems can save space.

3.Cost-effective: By combining several features, it reduces installation and maintenance expenses.

4.Simplified Installation: Installing this system is faster and easier than installing separate valves.

5.Diminished Leakage Points: A reduced number of joints and connections reduces the possibility of leaks.

Description:

Available materials: Cast iron, SS304, SS316, CF8, CF8M, Ductile iron

Size: 2” to 20”

Class: 125 to 300

Nominal Pressure: PN6 to PN25

Ends: Flanged

Operation: Handwheel