Our Shop

Contact us for all your questions and opinions, or you can solve your problems in a shorter time with our contact offices.

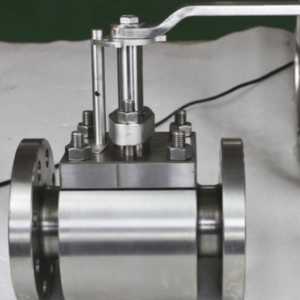

Zirconium Valves

ValvesOnly is the top Zirconium Valves Manufacturer in USA. Zirconium valves are made from zirconium or zirconium alloys, corrosion-resistant and of high temperature. One special metal highly valued for applications involving aggressive chemicals and extreme environments is zirconium, so valves made from this metal alloy apply to many industrial processes.

Working

Zirconium valves work somewhat similarly to the other types of valves; however, the incorporation of properties found in zirconium gives various benefits. Here is an overview on how such valves work. Zirconium valves are installed on pipelines to control the flow of liquid and gaseous fluids. They may be opened to allow flow or closed to stop it. They may be operated manually, by handwheels and levers, or automatically, through actuators. Generally, the inner mechanism of a valve would consist of some form of rotating or sliding piece-potentially a ball, gate, or plug-that would move to open or close the valve. When closed, a valve provides a tight seal without leaks to protect fluids within the system, thereby further preventing them from being carried off into unwanted places within the system-for example, through corrosive environments.

Advantages

1. Excellent Corrosion Resistance-Zirconium provides excellent resistance to a broad range of corroding environments from strong acids and alkalis, which classify them for chemical processing.

2. High-Temperature Stability-The valves retain their mechanical properties at high temperatures, hence providing reliable operation in high-heat applications.

3. Strength and Durability-Zirconium’s inherent strength adds up to the valves’ durability, providing the capability to resist wear-and-tear impacts over considerable periods.

4. Biocompatibility-Being non-toxic and biocompatible, it is used in some medical applications to ensure safety when in contact with biological systems.

5. Low Thermal Expansion-Because the coefficient of thermal expansion is low for zirconium, it is for a secure set of dimensions within variable temperatures.

6. Versatile. Valves made of zirconium can be used in any industry such as chemical processing, nuclear power, aerospace, or pharmaceutical.

7. Low Maintenance Requirement-The zirconium valve has good durability along with corrosion resistance. Hence it results in low maintenance that helps reduce the operational costs.

8. Excellent Service Abilities under Difficult Extremes-It can operate satisfactorily under extreme conditions such as high pressure and aggressive chemical conditions that will ensure system integrity and safety.

Industries using

Chemical processing plants

Nuclear reactors

Aerospace components

Components

Double gland adjusting design

Trunnion plug design

Live loaded Belleville spring

Advanced stem threefold sealed design

Packing box design

Plane bearing

Compact and robust body design

Fine tuning of the angle of plug

Showing all 3 results