Gate Valve

Valvesonly is a reputed manufacturer of Gate valves supplying to cities like Houston, Cleveland, Pittsburgh and Baton Rouge. A gate valve is often used to shut off the flow in the valve rather than regulate it. Because there are no obstructions in the flow path, this valve has a very low flow resistance. It prevents any kind of leaking. There are two positions for these valves: fully open and completely closed. When the gate valve is opened, the disc is completely removed from the flow stream. This valve provides a number of advantages over other valves. Gate valves are useful in a number of applications. They are used in the chemical, petrochemical, power generation, pulp & paper, and oil and gas refining industries.

Types:

- Rising Stem Gate valve

- Non Rising stem Gate valve

- Bellow Sealed Gate valve

- Pressure Seal Gate valve

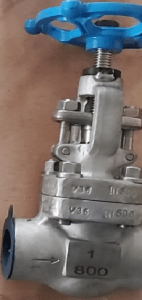

- Forged Gate valve

- Cryogenic Gate valve

Globe Valve

Various cities like Los Angeles, Chicago, Detroit and Houstan use globe valves for various industries like chemical, oil and gas and steel production. A globe valve’s major purpose is to start, stop, and regulate the flow of the medium that passes through it. This kind of valve can be used for both isolation and throttling. During valve opening and closing, the disc in the valve rotates perpendicular to the seat. The flow is directed up through the seat ring against the disc’s bottom, making installation of a Globe valve simple. This stops dirt from flowing through the valve.

Types:

- Y Type Globe Valve

- Angle Globe Valve

- Bellow Sealed Globe Valve

- Z Type Globe Valve

- Pressure seal Globe Valve

Industries that use Gate valve and Globe valve

Marine Industry: Globe valves are used in marine applications, such as shipbuilding and offshore platforms, for controlling the flow of water, fuel, and other fluids in various systems like cooling, ballast, and fuel supply.

Oil and Gas Industry: Globe valves are widely used in the oil and gas industry for controlling the flow of crude oil, natural gas, and various other fluids in pipelines and process systems.

Power Generation Industry: Globe valves are used in power plants for regulating the flow of steam, condensate, and other fluids in boilers, turbines, and cooling systems.

Chemical Industry: Globe valves find applications in the chemical industry for handling and controlling the flow of corrosive chemicals, solvents, and other hazardous fluids.

Water Treatment Industry: Globe valves are utilized in water treatment plants for regulating the flow of water, chemicals, and wastewater in various treatment processes such as filtration, disinfection, and purification.

HVAC Industry: Heating, Ventilation, and Air Conditioning (HVAC) systems often employ globe valves to control the flow of water or refrigerants in heating and cooling systems.

Pharmaceutical Industry: Globe valves are used in pharmaceutical manufacturing processes for controlling the flow of liquids and gases in the production of medicines and other pharmaceutical products.

Pulp and Paper Industry: Globe valves are utilized in pulp and paper mills for regulating the flow of water, steam, chemicals, and pulping agents in various stages of the paper production process.

Food and Beverage Industry: Globe valves find applications in the food and beverage industry for controlling the flow of liquids, such as water, milk, juices, and various ingredients, during processing and packaging.

Petrochemical Industry: Globe valves are employed in petrochemical plants for controlling the flow of petroleum products, chemicals, and gases in different production processes.

Recent Posts

- What Is a Steam Trap and How Does It Work?

- What Is a Foot Valve and Why Is It Used in Pumping Systems?

- BI-DIRECTIONAL VS. UNI-DIRECTIONAL KNIFE GATE VALVES: WHICH ONE DO YOU NEED?

- WHAT IS A DOUBLE BLOCK AND BLEED BALL VALVE? A COMPLETE GUIDE

- UNDERSTANDING THE DIFFERENT TYPES OF AIR VALVES: SINGLE VS. DOUBLE ORIFICE