Our Shop

Contact us for all your questions and opinions, or you can solve your problems in a shorter time with our contact offices.

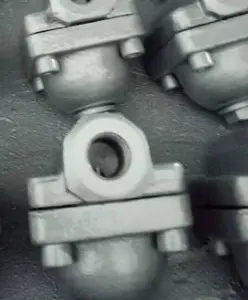

Bellow Seal Globe Valve

Valvesonly are premium Bellow Seal Globe Valve Manufacturers in USA. A bellows seal globe valve is a specifically made valve that is ideal for use in hazardous material-handling industries. Because of their special design, even the tiniest leaks are prevented, which can be crucial in some industries. This is especially crucial for sectors like the chemical and nuclear industries, where the movement of toxic, hazardous, highly poisonous, and combustible media through pipelines poses a significant danger of leakage, explosion, and health concerns. Therefore, the bellows seal globe valve satisfies particular, strict leakage and sealing requirements that are crucial in these kinds of sectors.

Working:

Bellows seal globe valves work by sealing the valve stem components with a compact form that incorporates bellows. To stop the system fluid from eroding the stem, the lower end of the stainless-steel bellows is welded to the stem inside the bellows valve. To establish a lasting seal, the other end is placed in between the valve’s body and cover. There is no leaking thanks to the double seal arrangement. To guarantee consistent operating efficiency and stop the valve stem from vibrating due to the movement of the valve insert, the bellows is welded to the valve stem.

Parts:

•Stem

•Body

•Handwheel

•Disc

•Bonnet

•Seat

•Bellows

•Gasket

•Packing Flange

•Packing Ring

Advantages:

1.No external leakage.

2.Reliable sealing performance.

3.Resistance Anti-corrosive

Industries:

•Natural Gas.

•LPG & LNG.

•Paper & Pulp.

•Chemical Industry.

•Petro – Chemical Industry.

•Textile Industry

Application:

1.Used in piping systems to avoid leakage.

2.Long distance fluid transportation.

Description:

Bellow Seal Globe Valve Manufacturer in USA has the valve with these specifications

Available material: WCB, WC6, SS304, SS316, DUPLEX STEEL,

Ends: Flanged

Class: 150 to 2500

Showing all 3 results