Our Shop

Contact us for all your questions and opinions, or you can solve your problems in a shorter time with our contact offices.

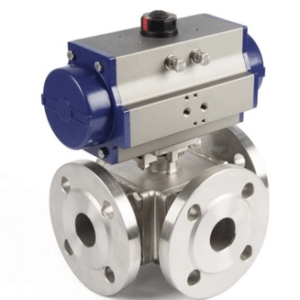

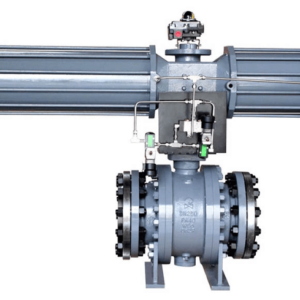

PNEUMATIC ACTUATED BALL VALVE

Valves Only is a leading Pneumatic Actuated Ball Valve Manufacturers in USA that introduces you to quality products that are made to resist harsh usage and peak performance in factories. For sectors where there is a need for efficient and mechanized flow control, pneumatically actuated ball valves are essential. Pneumatically operated ball valves see compressed air control the actuator and enable precise and rapid opening and shutting of valves.

Key Parts of a Pneumatic Actuated Ball Valve:

1)Valve Body: It is constructed of materials such as brass, carbon steel, or stainless steel.

2)Ball: To control fluid flow, the ball in the valve body rotates.

3)Seats: To seal the leaks tightly, provide a tight fit.

4)Stem: Transfers motion by linking the actuator to the ball.

5)Actuator: A pneumatic actuator uses compressed air to drive the valve.

6)Control System: Encompasses positioners, limit switches, and solenoid valves for automation.

Working Mechanism:

These valves operate by turning a ball within the valve body by a compressed-air-supplied pneumatic actuator. The actuator closes or opens the valve by turning the ball 90 degrees using air pressure. Automation is ideal for processes that require high efficiency as it offers fast, precise, and reliable flow control.

Advantages of Using Pneumatic Actuated Ball Valve:

1)Fast and Reliable Operation: ensures swift response times.

2)Ready for Automatic Operation: Suitable to connect easily with control systems.

3)Energy- Efficient: Compressed air is employed in lieu of power, rendering it energy-saving.

4)Leak- Proof: A reliable shut-off is delivered by the leakage-proof structure.

5)Low Maintenance Costs: Durable construction reduces running costs.

Types:

1)Single-Acting Pneumatic Ball Valve: Air is utilized to open or close a single-acting pneumatic ball valve, which returns through a spring.

2)Double-Acting Pneumatic Ball Valve: It opens and closes utilizing air.

3)Flanged Ball Valve: Offers safe connections for systems with high pressure.

4)V-Port Ball Valve: It provides precise flow control.

Industries:

1)Oil and Gas: Industries employ pneumatically operated ball valves to automate fluid flow in pipelines.

2)Chemical processing: Controls hazardous and hostile fluids.

3)Water Treatment: Makes it possible to ensure that water is delivered efficiently.

4)Pharmaceuticals: Provides precise flow control.

5)Power Plants: Control applications for steam and cooling water.

Description:

Body Material: Cast steel (WCB, WCC, WC6, LCC, LCB), Stainless steel (SS304, SS316), Carbon steel(CF8, CF8M),

Class: 150 to 2500; PN10 to PN450

Size: ½” to 4”

End: Buttweld, Flanged, Socketweld, Threaded

Operation: Pneumatic actuated ball valve

Configuration of a Pneumatic Actuator:

4-20 amp

Pneumatic single acting actuators

Pneumatic double acting actuators

Pneumatic rotary actuators

Pneumatic Scotch and Yoke actuators

Pressure: 228 bar

Temperature:

Standard -4°F to 200°F (-20°C to 93°C)

Low -40°F to 176°F (-40°C to 80°C)

High 0°F to 300°F (-18°C to 149°C)

Conclusion:

In those industries which require precise and automatic fluid handling, pneumatically driven ball valves play a critical role. Getting the optimal Pneumatic Actuated Ball Valve Manufacturers in USA assures effective and long-lasting products. Of all leading manufacturers of pneumatically controlled ball valves within the United States, Valves Only offers high-performance and reliable valves to multiple industries.

Showing all 11 results