AWWA Grooved Butterfly Valve

$140.00 – $791.00

In Stock

- Delivered today (order Mon-Fri before 12:00, delivery between 17:00 and 22:00)

- Including shipping costs, sent by valvesonly.com

- Pick up at a valvesonly.com collection point is possible

- 30 days to change your mind and free returns

- Day and night customer service

Description

AWWA Grooved Butterfly Valve

Body Construction: Grooved End

Face to face: MSS SP-67

Groove acc.to: AWWA C606

Top flange: EN ISO5211

Max Working pressure: PN16

Temperature: -20℃ to 140 ℃

Operation: Lever, Hand wheel, Electric Actuator, Pneumatic Actuator

Coating: Epoxy Coating

Disc: Bronze, Ductile iron rubber volcanized EPDM, NBR, Hypalon, Butyl

Tightness test: To EN12266-1:2003

Performance:

| Nominal pressure(Mpa) | 1.0 | 1.6 | |

| Nominal diameter(mm) | 50 to 1000 | 50 to 1000 | |

| Test pressure | Shell | 1.5 | 2.4 |

| (Mpa) | Seal | 1.1 | 1.76 |

| Applicable temperature | 150 | ||

| Applicable medium | Fresh water, Sewage, Sea water, Air, Vapour, Food, Medicine, Oils, Acids, Alkalis, etc. |

||

| Operating mode | manual, worm gear, pneumatic, electric, etc. | ||

Standard:

| Design & Manufacture | Flange Connection | Face to Face Dimension | Test & Inspection |

| MSS SP-67 API609 EN593 |

DIN PN10, 16, 25; ANSI B 16.1 BS4504; ISO PN10, 16 JIS B 2212, 2213 BS 10 table D; BS 10 table E |

API609 ISO5752 series 20 BS5155 |

API 598 |

Material List:

| NO. | Part Name | Material |

| 1 | Body | Carbon Steel, Stainless Steel, Cast Iron, Ductile Iron/, Al-Bronze |

| 2 | Disc | Al-Bronze, CF8M, Ductile iron, WCB |

| 3 | Seat | EPDM, PEFE, Buna, NBR, Hypalon |

| 4 | Stem | Carbon Steel, Stainless Steel314, Stainless Steel316 |

| 5 | Bushing | PTFE, Lubricating |

| 6 | O ring | EPDM, PEFE, Buna, NBR, Hypalon |

| 7 | Pin | SS316, SS416, SS304 |

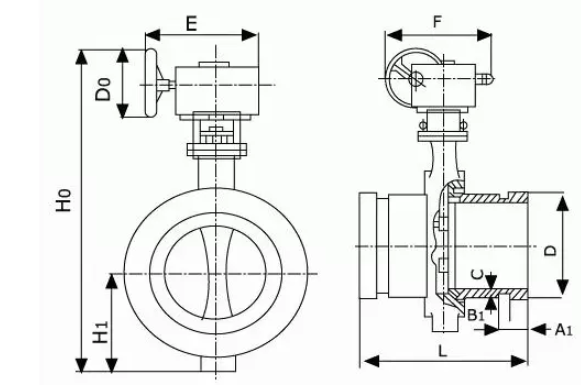

Dimension:

| Nominal diameter | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |||

| D | 57 | 60 | 76 | 89 | 108 | 114 | 133 140 | 159 165

168 |

219 | 273 | 325 | |

| A1 | 14.5 | 14.5 | 14.5 | 16 | 16 | 16 | 19 | 19 | 19 | |||

| B1 | 9.5 | 9.5 | 9.5 | 9.5 | 9.5 | 9.5 | 13 | 13 | 13 | |||

| C | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.5 | 2.5 | 3.3 | |||

| D381X

D81X |

L | 88 | 96 | 96 | 115 | – | 132 | 147 | 159 | 165 | ||

| H1 | 60 | 80 | 80 | 94 | – | 125 | 150 | 220 | 250 | |||

| H0 | 220 | 270 | 270 | 300 | – | 350 | 400 | 600 | 740 | |||

| E | 245 | 245 | 245 | 245 | – | 245 | 260 | 260 | 330 | |||

| F | 65 | 65 | 65 | 65 | – | 65 | 90 | 125 | 180 | |||

| D0 | 120 | 120 | 120 | 120 | – | 140 | 140 | 140 | 240 | |||

Additional information

| Body Material | Ductile Iron |

|---|---|

| Size | 10", 12", 2 1/2", 2", 3", 4", 6", 8" |

| Class | 150/PN16 |